Lots of Useful facts about Self Adhesive vinyl, and what you can do with it?

Self-adhesive vinyl is exactly what it says it is...Self-adhesive (or sticky) PVC (vinyl).

Because it's basically very thin waterproof plastic (PVC) and sticky-backed, it can be made into, or used for all manner of labelling, graphics, markings etc etc etc. If you think about it, there's absolutely no difference between a huge printed graphic on the side of a bus or a tiny label that goes onto something.

The only (main) thing that is different is the size.

Self-adhesive vinyl is made of three bits:

1. The thin PVC film

This is the waterproof film that gets printed on.

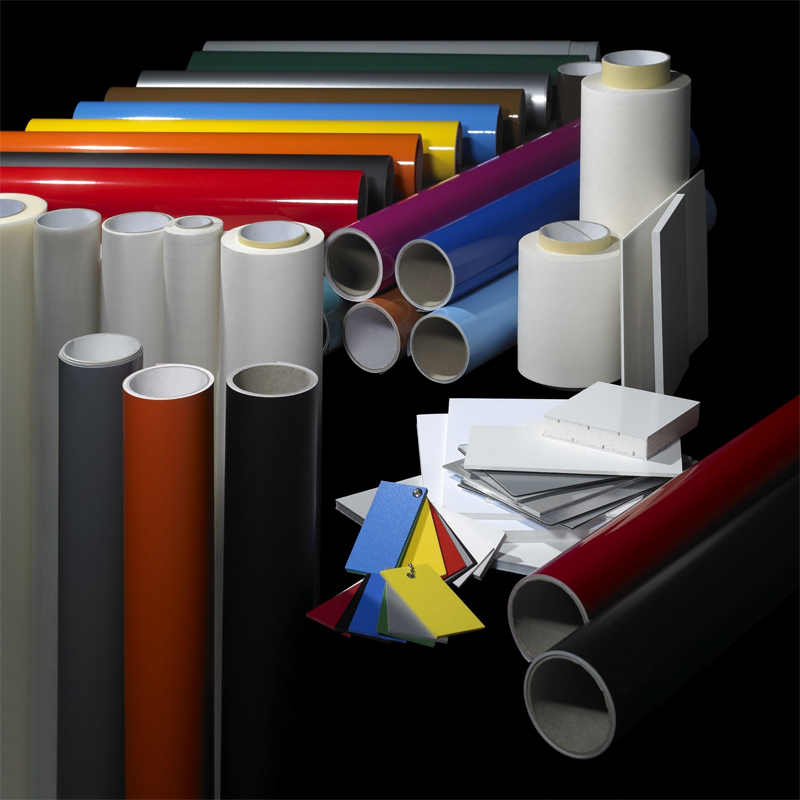

For the vast majority of printed work, this is either WHITE or CLEAR, although it is available in a whole range of colours and metallics etc for either cut-out coloured lettering (with no printing), or more specialist metallic, dayglo, glow in the dark or other things.

The thickness of the vinyl film also varies. The average is about 90/100 micron, although it is available thinner. Surprisingly, thinner vinyl is more expensive, as it's made in a different way to be more pliable, softer and flexible. This is important for fitting onto some awkward things like vehicles where the panels aren't flat. This is called Calendared vinyl.

2. The Adhesive

This is the glue that is coated onto the back of the vinyl film.

embossed stickers

There are different types of adhesive, mainly:

Ultra removable

This is a very low tack adhesive that is used where the label or graphic needs to stick but be easy to peel off without leaving any mess behind.

Removable

This is a stronger adhesive, but still removable, as above. HOWEVER, if it's left for a long time, it does become quite hard to get off!

Permanent

This is as it says, permanent. It sticks permanently, once it's had time to ‘set' It can be removed by warming it up with something like a hairdryer, as this softens the adhesive.

High Tack

This isn't any more permanent than Permanent, but it is ‘stickier', and it has more ‘grab' than the other adhesives. It's used where the label/graphic is going onto awkward surfaces that other adhesives don't like to stick to.

3. The backing paper

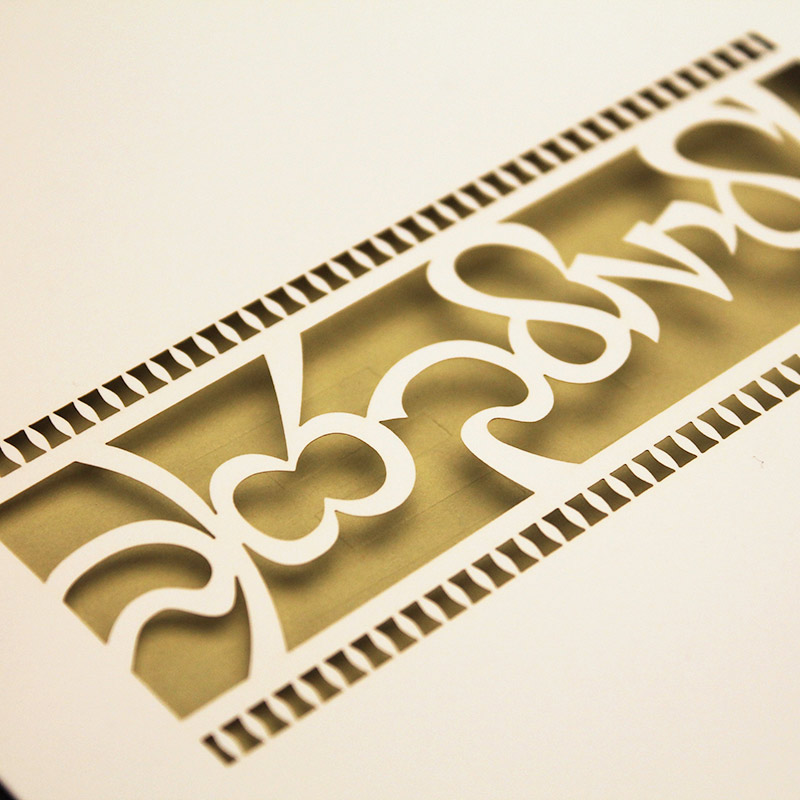

This is a waxy paper that the vinyl comes stuck to. When labels are ‘kiss cut' to shape, only the surface vinyl is cut through, leaving the backing paper intact as a backing sheet.

…and then there's surface over-laminating if it's needed.

For some end-uses, a surface over-laminate is applied, after the printing, on top of the ink.

This gives the ink (and vinyl) and protective layer to stop it scuffing off, and makes the sticker more hard-wearing. As it's another process, it obviously adds more cost to the price of making the stickers/labels. There are different laminates available: Matt, gloss, anti-slip (for floor graphics), dry wipe, etc.

More sticker and vinyl facts:

embossed stickers

A surface needs to be free of dust or muck before you apply the sticker.

You can remove most stickers by warming them up with a hairdryer, as the heat makes the adhesive go soft again.

If you want to cover something over with a sticker, then you need to use opaque vinyl. This is made of either an opaque PVC film or in some cases black adhesive is used. They both work.

You can't test if a sticker is going to ‘stick' by rubbing it down and then peeling it straight off.

The adhesive needs time to do its thing and get a good hold. This takes a few hours, minimum.

There are lots of ways of fitting stickers without leaving loads of air bubbles.

China Import and Export Fair

China Import and Export Fair Focus On Products

Focus On Products