The stage to make a vinyl film is to compound the PVC rosin into little pellets. There ar 2 ways that to manufacture vinyl film: basting or calendaring. To retell Associate in Nursing earlier purpose, thanks to the flexibility of the mixture of PVC and also the additives, the standard differs between the 2 processes. Casting films leads to a high-grade product whereas calendaring films is a lot economical method. Hudson show Services restricted describes the 2 processes of cooking; casting films is comparable to “baking a cake,” which involves gushing a liquid mixture into a casting sheet and is processed through a series of ovens, in the meantime calendaring films is comparable to “pizza dough” wherever the batch is “mixed and heated to a liquified state” and is then “extruded through a die and is then fed through a series of calendaring rolls.”

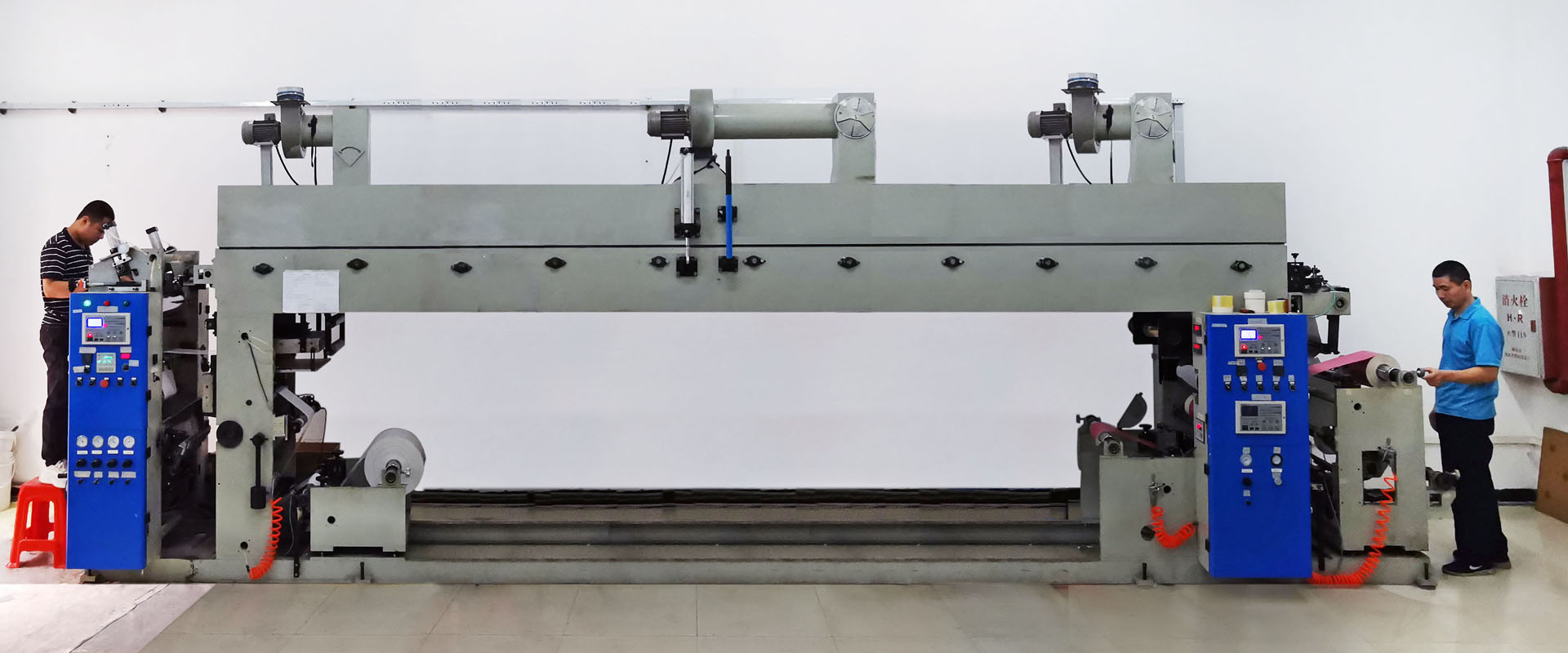

This paper can specialize in the calendaring method to create the vinyl film. to rework the white powder that's PVC rosin to a vinyl film, a few of alternative materials ar additional in. a very important ingredient to feature is that the softener, a transparent liquid that softens the PVC rosin and adds flexibility to the ultimate product. in keeping with John Hingst, “normal vinyl films employed in graphics applications contain between two hundredth and twenty-fifth plasticizer… The plasticizer’s relative molecular mass helps verify its stability. Higher-molecular-weight, chemical compound softener includes terribly huge, bulky, slow molecules. Hence, they keep within the film.” subsequent few additives are optional: stabilizers like ultraviolet illumination absorbers that defend the film from ultraviolet illumination lights and chemical reaction, pigments to alter the vinyl film color. once the PVC rosin, plasticizers, and nonmandatory additives are blending along, it's fed into the Associate in Nursing extruder till the “fine powder melts, at close to 300°F, the extruder kneads the fabric into a hot, twisted plastic rope. The extruder conjointly helps strain out any foreign particles, that might injury the machinery” (Hingst). The plastic rope is fed through calendaring rolls as heat frequently will increase, permitting the vinyl film to become a lot malleable. The film is squeezed through many a lot of calendaring rolls till it's as skinny because of the vinyl stickers we tend to ar accustomed to seeing. Last, but not least, the film passes through another set of rollers that cool the vinyl sheets, then another set of rollers that provides it a surface end, then aroused “to minimize any tension that might lead to future, dimensional-stability issues” (Hingst).

Currently, the subsequent stage of the vinyl stickers, the application of the adhesive on the vinyl film, is predicated on assumptions for the rationale that there was no mention of the precise variety of adhesive used. Since totally different additives may be blending with the PVC rosin, and 2 totally different producing processes, the sort of vinyl stickers will defer. as an example, waterproof vinyl stickers would have a unique adhesive compared to 1 that may be applied on the wall or on a portable computer. Common adhesives used for vinyl stickers ar solvent-based acrylic adhesives (Hudson). These acrylic adhesives are ar artificial, derivation typically from crude additionally (Brett). Another facet that was conjointly troublesome to search out was however the adhesive can be applied to the vinyl film. Therefore, as a substitute, or as a potential means the adhesive can be applied, I found a video illustrating how adhesive tapes are factory-made and applied adhesive (How It’s created | Adhesive Tape). The adhesive method is comparable to the start method of PVC rosin wherever additives like ultraviolet illumination protectors, antioxidants, color pigments, and artificial rosin are mixed along (Adhesive Tape). This explicit adhesive is named hot soften and is loaded into a holding tank that maintains heat (at 102 degrees Fahrenheit) because it is tense onto a slanted edge so the liquid adhesive will unfold onto the tape film because it is wound.

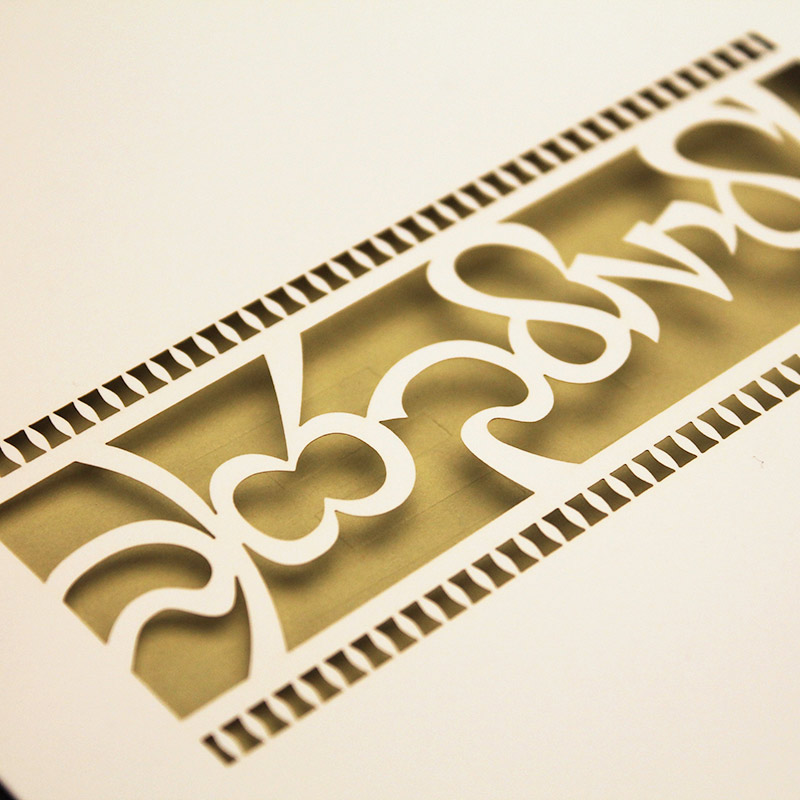

The subsequent stage is additionally nonmandatory because it depends on what quiet vinyl stickers are created. Vinyl stickers may be minimalistic, merely cut by a cutting plotter. Or the vinyl stickers will have graphics on them which implies specific inks got to be chosen and support the sort of vinyl is employed. because the reoccurring theme of this paper is: that PVC is flexible, thus its product, vinyl, is flexible.

After a long journey, especially the production of the vinyl film as that was the majority of the paper, the vinyl stickers are packaged in plastic and cardboard for distribution and transport. However, this process splits off as vinyl stickers can also be made by the consumers. They can purchase rolls or sheets of self-adhesive vinyl and print and cut out their own stickers. After use, vinyl stickers are generally not recyclable because they can get caught in the recycling machines, thus it is suggested that the consumer can reapply adhesives to the back of the vinyl stickers. Otherwise the last resting place for the vinyl stickers is the landfills. Throughout this research experience, my indifference towards vinyl stickers morphed into questioning as the more I tried to find one definite process, are vinyl stickers (and stickers in general) worth the trouble of this whole process? PVC can be made into many different products, such as pipes, and has many useful physical properties such as fire retarding properties and oil/chemical resistance (PVC).

China Import and Export Fair

China Import and Export Fair Focus On Products

Focus On Products