Primarily, selecting the correct vinyl depends on 2 factors: what you're applying the vinyl to, e.g., brick, wood, windows, signage, cars, and the way long it has to be there. Therefore, location and required endurance can confirm the sort of vinyl you utilize moreover as that adhesive is best to use it.

The Different forms of Vinyl

Vinyl is formed in one in all 2 ways—by ‘calendering’ or by ‘casting.’ each ways use an equivalent ingredients, with the first element being a polyvinylchloride compound (PVC) together with a softener to administer the vinyl its flexibility and pigment for color.

Calendered Vinyl

‘Calendered’ vinyl is factory-made mistreatment Associate in Nursing ‘extruded’ or ‘rolled’ method. the method of producing glossy vinyl is a smaller amount effortful, thus it's a great deal cheaper than ‘cast’ vinyl. betting on the molecular structure of the softener used throughout producing, a ‘calendered’ vinyl is either ‘monomeric‘ or ‘polymeric.‘. glossy vinyls ar amongst the foremost fashionable vinyls for each short term and future regular assemblage applications. Innotech’s vary

Monomeric Vinyl

A softener with a smaller molecular size is employed for ‘monomeric’ vinyl, which implies it's a lot of impact on the adhesive and laminates used. This smaller molecular size makes the vinyl brittle once utilized in stringent environmental conditions, thus there'll be shrinkage or ‘pulling.’

Monomeric self-adhesive forms of vinyl ar thick and stiff. they need Associate in Nursing expected out of doors lifetime of 3-5 years for black and white and 2-3 years for colours, that makes them appropriate for indoor applications and short-run out of doors applications. {they come|they ar offered} in matt and gloss finishes and are the foremost economic vinyl available. because of their rigidity, they must be used for flat applications solely.

Polymeric Vinyl

Due to the larger size of molecules and their longer chains, ‘polymeric’ forms of vinyl have less impact on the adhesive and laminates used, which provides this vinyl a lot of flexibility and ends up in less shrinkage. It additionally lasts longer. The plasticizers utilized in producing ‘polymerics’ create it a way higher vinyl on that to print.

Polymeric self-adhesive vinyl is softer and almost as thick as monomeric forms of vinyl and, therefore, usually has five hundredth less shrinkage than monomeric vinyl. they're softer and may adapt to contours as long as they're not too sophisticated. they need an out of doors lifetime of 7-8 years for black and white, 5-7 years for colours, and 3 years for Metallics. they're typically offered in an exceedingly gloss end however do additionally are available clear and matt finishes.

Cast Vinyl

The producing method of ‘cast’ forms of vinyl is way less stressed. a skinny layer of organic compound is poured on a really sleek surface and so passes through action ovens. the assembly prices ar higher, that makes forged vinyl dearer.

Cast self-adhesive vinyl is usually agent and soft to handle. It additionally lasts longer with an out of doors lifetime of ten years for black and white, seven years for colours, and 5 years for metallics. This vinyl ought to be used once you want it to evolve to contours like vehicle wrapping, as an example.

Adhesives for Applying Vinyl

Acrylic Adhesives

Generally, makers within the self-adhesive vinyl assemblage market standardize on acrylic adhesives for external, permanent applications. Adhesives developed specially to be compatible with the life of the vinyl being employed.

Acrylic adhesives ar either solvent-based or emulsion/water-based acrylics. Solvent-based adhesives or actinic radiation polyacrylate adhesives ar typically the simplest choices.

Although they're dearer, actinic radiation polyacrylate adhesives ar a lot of forgiving to temperature fluctuations throughout application and have wonderful out of doors sturdiness. They even have a bonus over solvent-based adhesives in this no dangerous solvents ar utilized in the coating method, and it's easier to figure with on more difficult surfaces.

Aqueous or emulsion-based adhesives price less however ar a lot of sensitive to temperature and don't last as long on out of doors applications.

Innotech’s vary comprehend all adhesive varieties – speak to 1 of our team to search out out a lot of.

Glues for Vinyl Applications

Clear glue is usually used for vinyl applications, however in some instances, gray glue could also be needed to feature a lot of opacity to the vinyl. Associate in Nursing example would be if you're applying the vinyl over existing graphics and wish to make certain they are doing not show through the new application.

General Formulations have additionally developed a special glue, that is high tack however removable. it's the glue properties of a high tack adhesive, however it may be removed while not going away residue up to six months when application. this suggests it’s a breeze for installation, however is additionally very simple to get rid of once the time comes.

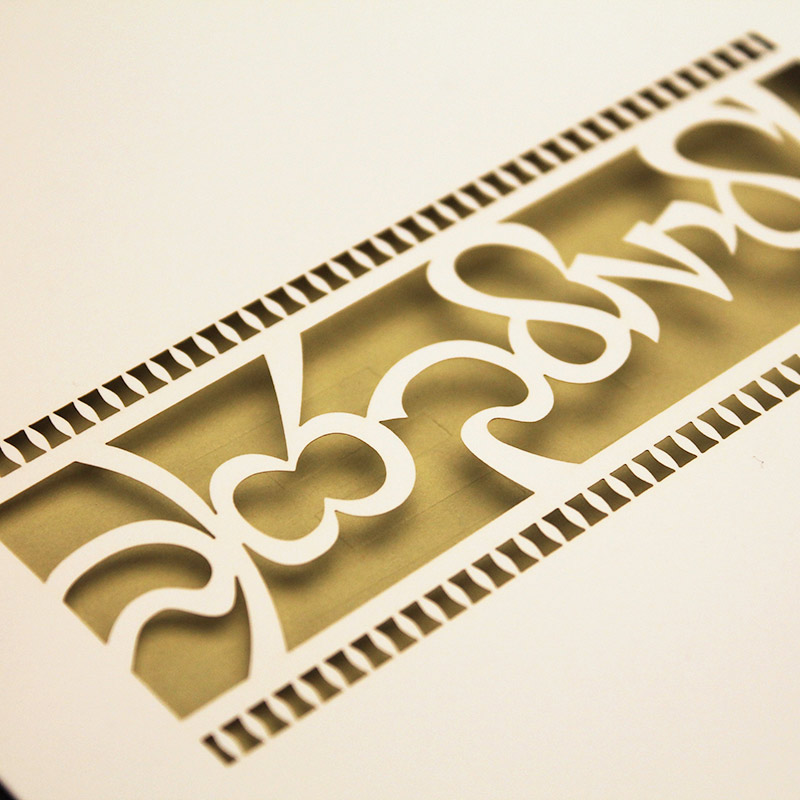

Air-Release Liners

You will notice that some forms of vinyl accompany air-release or air-escape liners. These ar largely liners that ar slightly decorated with a pattern that transfers onto the glue. Air-escape liners create the applying of the vinyl utterly untroubled because the air escapes from beneath.

Hopefully, you currently have a stronger plan of the probabilities of the assorted forms of self-adhesive vinyl, and you’re well equipped to settle on the correct vinyl for your specific application.

Recent web log Posts

Why PVC Free Print Materials Matter

The Window of Opportunity: Graphics For Glazing

Opportunities At Your Feet: A Guide To Floor Graphics

Focus not concern – Innotech’s 4-Point Response to The Coronavirus Pandemic

How to select the correct Self Adhesive Vinyl for the duty

Innotech Launches business initial – Print Material made up of Recycled

China Import and Export Fair

China Import and Export Fair Focus On Products

Focus On Products