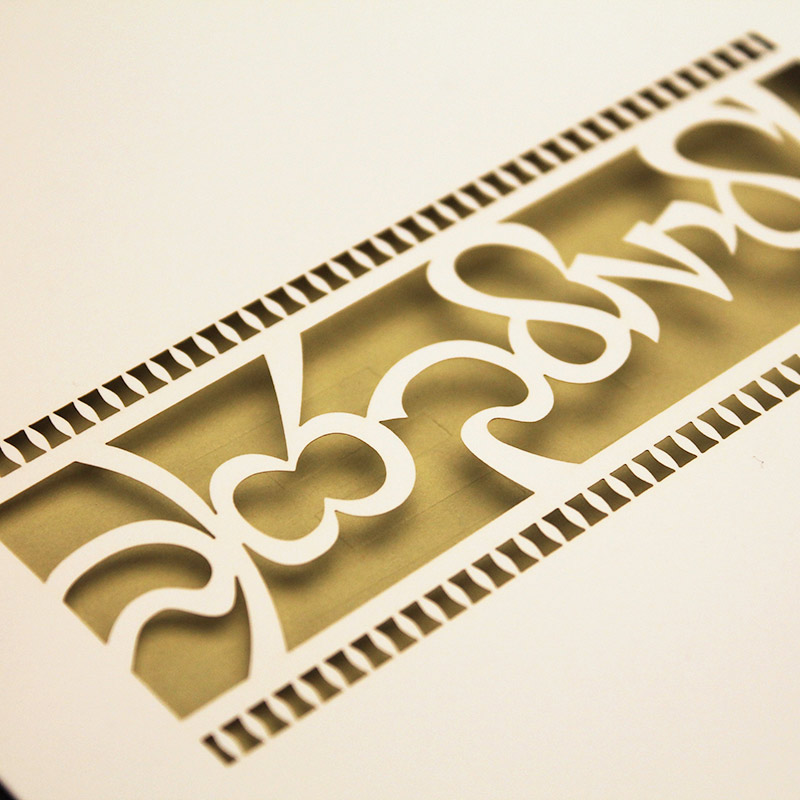

The Dryapply technology is specially designed for dry gluing large surfaces and guarantees easy processing. The finest air ducts allow easy extraction of bubbles during bonding. Thus, the application of the film without water is clean, fast and thus efficient.

Why should ASLAN films be glued only dry with Dryapply technology?

They must not be glued wet, otherwise water accumulates in the air ducts. This means that the end glue force is reached much later and a white colour can occur.

Can the film be corrected during gluing?

Due to a special glue, the initial adhesive force is lower and can therefore be well corrected during gluing.

This reduces the risk of a white fracture to a minimum.

Does the airway structure ever disappear?

The visibility of the structure decreases with time and depending on humidity and temperature

Minimum. It can only be seen from close range.

Which application tape is best suited?

An application tape with medium (UniversalTape ASLAN TP 122) or high adhesive force (HighTackTape ASLAN TP 136) should be used to glue the ASLAN films with Dryapply technology. The tape can be removed immediately after gluing, which saves time compared to wet gluing.

The edges of my adhesive glass decorative film with Dryapply technology are white.

What did I do wrong?

In case of window glues we recommend to keep a distance of approximately 2 mm from the foil to the rubber sealing of the window frame. This allows a collection of water and the associated whitening of the cut edges

and the reduction of adhesive force are avoided.

What do I have to pay attention to when gluing digital printed glass decorative foils with Dryapply technology?

Depending on the type of ink used, the film may become softer in individual cases, making it more difficult to glue. In order to ensure a smooth and safe adhesion, we recommend the use of an application tape; even with flat motifs.

China Import and Export Fair

China Import and Export Fair Focus On Products

Focus On Products