Self-adhesive vinyl has three layers – Polyvinyl chloride (PVC) film, an adhesive layer, and silicone release liner. The polyvinyl chloride (PVC) can be monomeric or polymeric. Its thickness may vary from 50 to 200 microns. Over the years had been created a non-PVC vinyl.

1. What are monomer and polymer?

A monomer comes from “mono”- one and “mer” – part. A molecule that can react together with other monomer molecules to form a large polymer chain. Polymers are large chain molecules composed of multiples of simpler units monomers. In conclusion, polymers are more complexed monomer molecules. The word polymer comes from “poly” – many and “mer” – part. The polymer could be naturally occurring or synthetic. Because polymers are composed of monomers, they are strong, more durable, and more reliable to operate.

2. Monomeric PVC vinyl

Monomeric vinyl uses the plasticizers with low molecule size. Monomeric films are made of short-chain plasticizers that make the product not resistant to heating, cooling, and brittle. You can recognize the old monomeric vinyl by the typical PVC layer cracks, due to its weak monomeric chains. After stretching monomeric vinyl usually broke or shrink. This type of vinyl is unbefitting for car wrapping unless is for short-term promotional purposes.

3. Polymeric PVC vinyl

Polymeric vinyl is made of long-chain plasticizers. That is why it is more stable, resistant to temperature changes, and has more stretching skills. It is preferable for interior, and exterior usage, and its durability is longer.

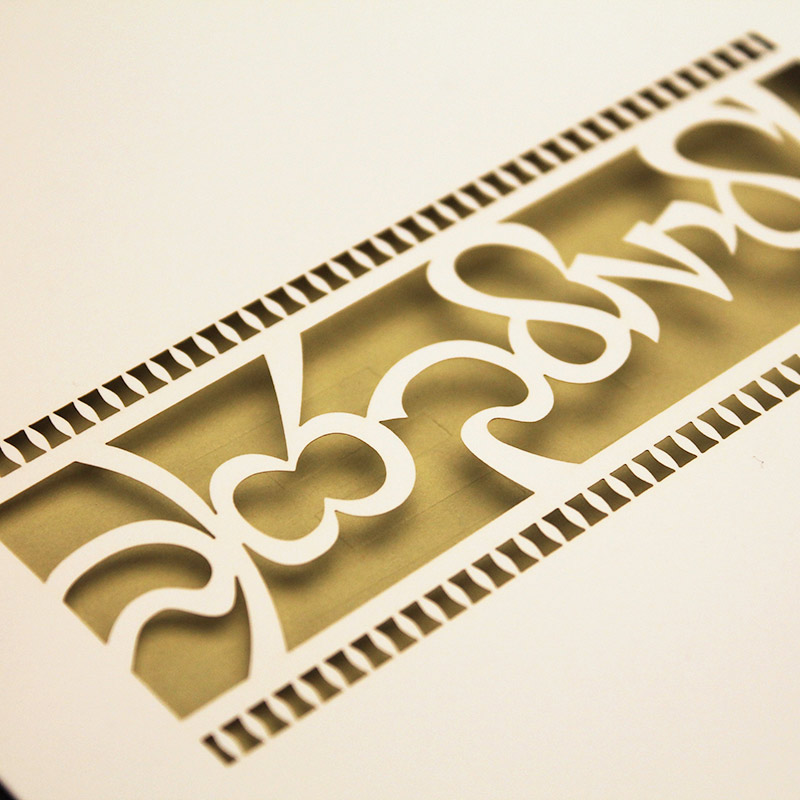

4. Polyester vinyl

All the sun-protecting, impact-resistant, and decorative glass vinyl are created of polyester. One of the best 3M high-technology series is Sun Control Film Prestige. There are over 200 nanolayers in 38 microns thickness.

5. Non-PVC vinyl

Besides PVC, there is also polyurethane vinyl. 3M created series 3М Envision Print Film 48C and 3М Envision Print Film 480 – non-PVC vinyl. PVC is one of the most toxic plastics that cause environmental pollution. The number of countries and companies which banned the usage of PVC rise numerously. Also, the European Parliament has voted to fully ban the PVC in the next 10 years.

The biggest advantage of non-PVC vinyl is fully restrained shrinkage. 3M series 480 allows easy stretching up to 180% and this is something that even 3M’s flagman cast vinyl IJ180mC cannot do. Countries increasingly prefer non-PVC vinyl for car wrapping due to two big advantages. The easy application and the fact that is fully Eco-friendly – suitable for any kind of green company.

6. Masterbatches (additive)

Masterbatches (additive)

All of the PVC products consist of additives, they are called masterbatches. They improve the product’s UV absorbance, flexibility, durability, thermal resistance and make them antimicrobial.

Masterbatches can be also a solid additive for plastic used for coloring. The main part of calculating the whole price for the self-adhesive PVC film is the fact PVC is very cheap itself, but the added masterbatches can add up to 50% to the price. They improve the quality and extend durability.

3M vinyl technology uses the highest class masterbatches additive. The color quality is one of the most recognizable differences. If you compare the 3M color palette with some others, you would notice that 3M’s colors pigment is way more clear and bright.

Furthermore, 3M pays special attention to the PVC’s UV stabilizers and plasticizes. Most of the professionals in this community said that 3M’s vinyl is much better, compared to the same class vinyl but from different manufacturers.

China Import and Export Fair

China Import and Export Fair Focus On Products

Focus On Products