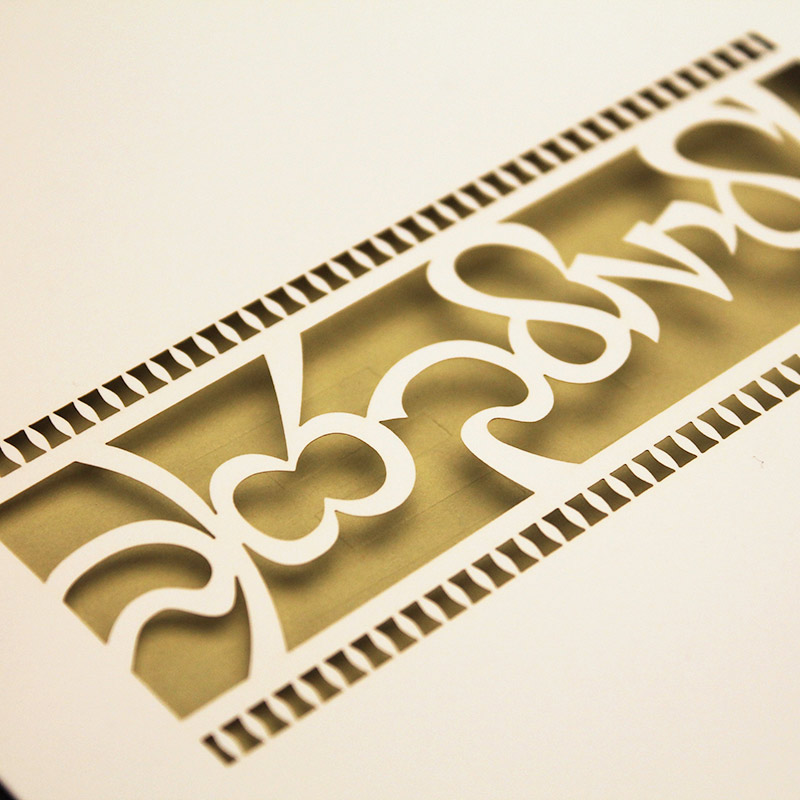

What does PVC have to do with the bumper stickers on the back of your truck or the wall decals in your living room? Well, I'm glad you asked. The PVC is converted into flat sheets and married to pressure sensitive adhesive in order to create sticker vinyl. If you really want to break the process down to its foundation, it's the blending of a polymerized colorless gas and a sticky glue we in the decal industry like to call, "adhesive."

Once those two sheets are "married," we have the foundation for all the stickers and decals you can imagine. Now comes the fun part: These sheets aren't limited to any particular color, thickness, or size. As you probably guessed, the normal color of the sheets is white, but look around: there are stickers of all colors, shapes, sizes, and thicknesses all around you. Some are customized out of necessity. Others are customized simply to be different. That covers the raw materials. Now, let's starting designing!

What will PVC do with the bumper stickers on the rear of your truck or the wall decals in your living room? Well, I am glad you asked. The PVC is born again into flat sheets and married to the pressure-sensitive adhesive so as to form sticker vinyl. If you actually need to interrupt the method right down to its foundation, it is the mixing of a polymerized colorless gas and a sticky glue we tend to within the decal trade wish to decision, "adhesive."

Once those 2 sheets of area unit "married," we've got the muse for all the stickers and decals you'll imagine. currently comes the fun part: These sheets are not restricted to any specific color, thickness, or size. As you almost certainly guessed, the traditional color of the sheets is white, however, look around: there are unit stickers of all colors, shapes, sizes, and thicknesses all around you. Some area unit made-to-order out unavoidably. Another area unit is made-to-order merely to show a discrepancy. That covers the raw materials. Now, let's begin designing!

China Import and Export Fair

China Import and Export Fair Focus On Products

Focus On Products